●Sintered NdFeB hlau nplaumtau siv dav rau lawv cov khoom sib nqus zoo kawg li. Txawm li cas los xij, cov hlau nplaum 'tsis zoo corrosion kuj cuam tshuam lawv cov kev siv ntxiv hauv kev lag luam, thiab cov txheej txheem saum npoo yog tsim nyog. Cov txheej siv dav siv tam sim no suav nrog electroplating Ni-Raws li txheej txheej, electroplating Zn-raws licoatings, nrog rau electrophoretic los yog tshuaj tsuag epoxy txheej. Tab sis nrog kev nce qib ntawm kev siv thev naus laus zis, cov kev xav tau rau cov txheej txheemof NdFeBkuj tseem nce ntxiv, thiab cov txheej txheem electroplating tej zaum tsis tuaj yeem ua tau raws li qhov yuav tsum tau ua. Al-raws li txheej tso siv lub cev vapor deposition (PVD) tshuab muaj cov yam ntxwv zoo heev.

● Cov txheej txheem PVD xws li sputtering, ion plating, thiab evaporation plating tuaj yeem tau txais cov txheej txheem tiv thaiv. Table 1 teev cov qauv thiab cov yam ntxwv sib piv ntawm electroplating thiab sputtering txoj kev.

Table 1 Kev sib piv cov yam ntxwv ntawm electroplating thiab sputtering txoj kev

Sputtering yog qhov tshwm sim ntawm kev siv cov khoom siv hluav taws xob siab los ua ib qho khoom nto, ua rau cov atoms thiab cov molecules ntawm cov khoom nto los pauv lub zog kinetic nrog cov khoom siv hluav taws xob siab, yog li txaws tawm ntawm cov khoom nto. Nws tau pom thawj zaug los ntawm Grove hauv xyoo 1852. Raws li nws lub sijhawm txhim kho, muaj kev sib tw thib ob, tertiary sputtering, thiab lwm yam. Txawm li cas los xij, vim tsis muaj kev sib txuas lus tsis zoo thiab lwm yam laj thawj, nws tsis tau siv dav txog xyoo 1974 thaum Chapin tau tsim cov magnetron sputtering sib npaug, ua rau kev kub ceev thiab qis kub sputtering qhov tseeb, thiab magnetron sputtering tshuab tau tsim sai. Magnetron sputtering yog ib txoj kev sputtering uas qhia txog electromagnetic teb thaum lub sij hawm sputtering txheej txheem kom ionization tus nqi mus rau 5% -6%. Lub schematic daim duab ntawm balanced magnetron sputtering yog qhia nyob rau hauv daim duab 1.

Daim duab 1 Daim duab qhia txog kev sib npaug magnetron sputtering

Vim nws zoo heev corrosion kuj, Al txheej deposited los ntawmion vapordeposition (IVD) tau siv los ntawm Boeing ua ib qho kev hloov rau electroplating Cd. Thaum siv rau sintered NdFeB, nws feem ntau muaj qhov zoo hauv qab no:

1.High nplaum lub zog.

Lub zog nplaum ntawm Al thiabNdFeBFeem ntau ≥ 25MPa, thaum lub zog nplaum ntawm cov electroplated Ni thiab NdFeB yog li 8-12MPa, thiab lub zog nplaum ntawm electroplated Zn thiab NdFeB yog li 6-10MPa. Cov yam ntxwv no ua rau Al / NdFeB haum rau txhua daim ntawv thov uas xav tau lub zog nplaum siab. Raws li pom nyob rau hauv daim duab 2, tom qab alternating 10 cycles ntawm kev cuam tshuam ntawm (-196 ° C) thiab (200 ° C), lub nplaum lub zog ntawm Al txheej tseem zoo heev.

Daim duab 2 daim duab ntawm Al/NdFeB tom qab 10 alternating cyclic impacts ntawm (-196 ° C) thiab (200 ° C)

2. Soak hauv cov kua nplaum.

Al txheej muaj hydrophilicity thiab lub kaum sab xis ntawm cov kua nplaum yog me me, tsis muaj kev pheej hmoo ntawm kev poob. Daim duab 3 qhia txog 38mN ntotension kua. Cov kua ntsuas no tau kis tag rau ntawm qhov chaw ntawm Al txheej.

Figure 3. kev xeem ntawm 38mN ntonruj

3.Qhov sib nqus permeability ntawm Al yog tsawg heev (tus txheeb ze permeability: 1.00) thiab yuav tsis ua rau shielding ntawm magnetic zog.

Qhov no tseem ceeb tshwj xeeb hauv kev siv cov hlau nplaum me me hauv 3C teb. Kev ua haujlwm saum npoo yog qhov tseem ceeb heev. Raws li pom hauv daim duab 4, rau D10 * 10 qauv kem, lub zog ntawm Al txheej ntawm cov khoom sib nqus yog tsawg heev.

Daim duab 4 Kev hloov pauv hauv cov khoom sib nqus ntawm sintered NdFeB tom qab tso PVD Al txheej thiab electroplating NiCuNi txheej rau saum npoo.

4.Lub uniformity ntawm lub thickness yog zoo dua

Vim tias nws tau muab tso rau hauv daim ntawv ntawm cov atoms thiab atomic pawg, cov tuab ntawm Al txheej yog tswj tau tag nrho, thiab qhov sib xws ntawm cov tuab yog zoo dua li cov txheej electroplating. Raws li pom hauv daim duab 5, Al txheej muaj cov tuab tuab thiab muaj zog nplaum zoo heev.

Daim duab5 hla ntu ntawm Al/NdFeB

5.The PVD technology deposition txheej txheem yog kiag li ib puag ncig tus phooj ywg thiab tsis muaj ib puag ncig muaj kuab paug teeb meem.

Raws li cov kev xav tau xav tau, PVD thev naus laus zis tuaj yeem tso nyiaj ntau, xws li Al / Al2O3 multilayers nrog corrosion kuj zoo heev thiab Al / AlN txheej nrog cov khoom zoo heev. Raws li pom nyob rau hauv daim duab 6, tus ntoo khaub lig-sectional qauv ntawm Al / Al2O3 multilayer txheej.

Figub 6Hla ntuntawm Al/Al2O3 multilyaers

Tam sim no, cov teeb meem tseem ceeb txwv kev lag luam ntawm Al txheej ntawm NdFeB yog:

(1) Rau sab ntawm cov hlau nplaum yog sib npaug. Qhov yuav tsum tau muaj kev tiv thaiv hlau nplaum yog tso rau qhov sib npaug ntawm txheej txheej ntawm cov hlau nplaum, uas yuav tsum tau daws qhov kev sib hloov ntawm peb sab ntawm cov hlau nplaum hauv batch ua kom ntseeg tau tias cov txheej txheem zoo sib xws;

(2) Al txheej stripping txheej txheem. Nyob rau hauv cov txheej txheem kev lag luam loj loj, nws yog ib qho inevitable uas cov khoom tsis tsim nyog yuav tshwm sim. Yog li ntawd, nws yog ib qho tsim nyog los tshem tawm cov txheej txheem Al txheej tsis tsim nyog thiabrov tiv thaivnws tsis ua rau kev ua haujlwm ntawm NdFeB hlau nplaum;

(3) Raws li ib puag ncig daim ntawv thov, sintered NdFeB hlau nplaum muaj ntau qib thiab cov duab. Yog li ntawd, nws yog ib qho tsim nyog los kawm txog kev tiv thaiv tsim nyog rau cov qib sib txawv thiab cov duab;

(4) Kev tsim cov khoom siv ntau lawm. Cov txheej txheem ntau lawm yuav tsum ua kom muaj kev tsim nyog tsim nyog, uas yuav tsum tau tsim cov khoom siv PVD tsim nyog rau NdFeB hlau nplaum tiv thaiv thiab nrog kev ua haujlwm siab;

(5) Txo tus nqi ntawm PVD technology ntau lawm thiab txhim kho kev lag luam kev sib tw;

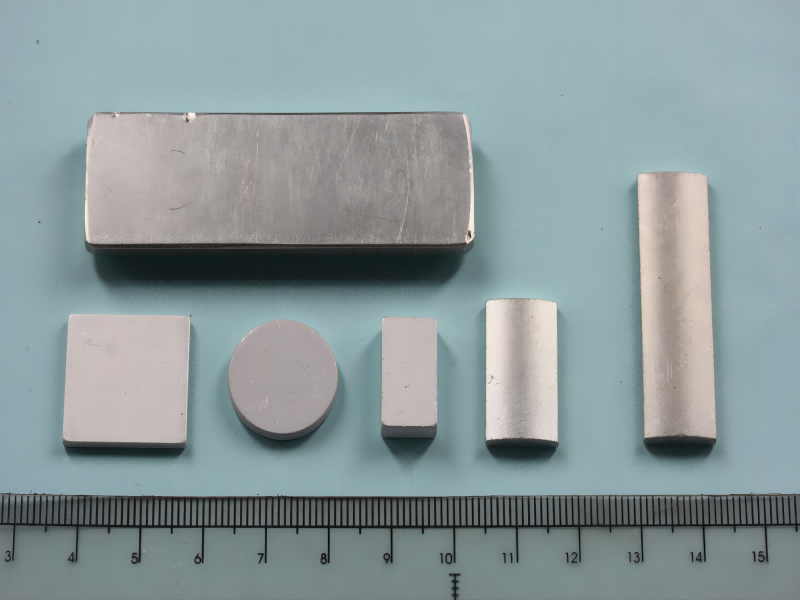

Tom qab xyoo ntawm kev tshawb fawb thiab kev tsim kho kev lag luam. Hangzhou Magnet Fais Fab Technology tau tuaj yeem muab cov khoom lag luam PVD Al plated ntau rau cov neeg siv khoom. Raws li pom nyob rau hauv daim duab 7, cov duab cov khoom muaj feem xyuam.

Daim duab 7 Al coated NdFeB hlau nplaum nrog cov duab sib txawv.

Post lub sij hawm: Nov-22-2023