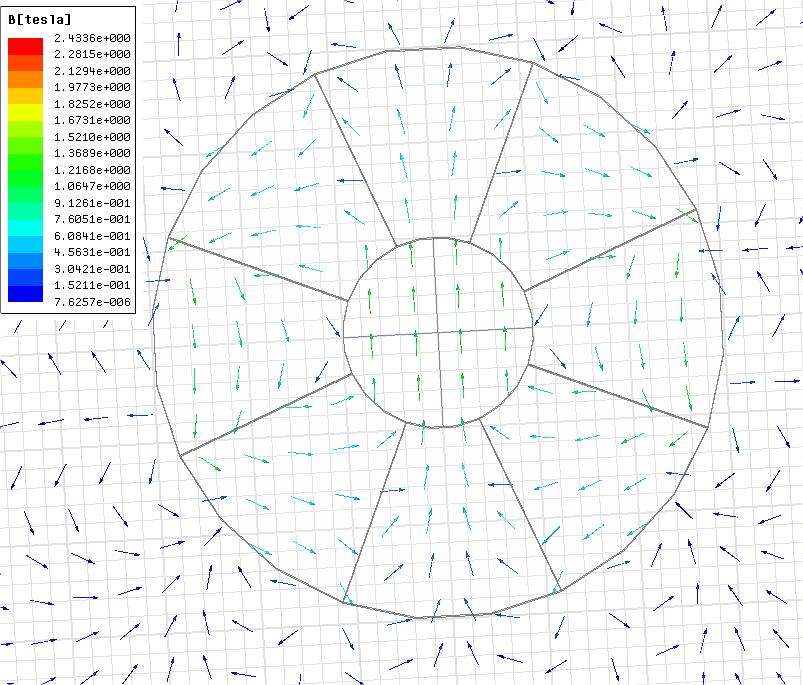

Halbach array is a special permanent magnet arrangement structure. By arranging permanent magnets at specific angles and directions, some unconventional magnetic field characteristics can be achieved. One of its most notable features is its ability to significantly enhance the magnetic field strength in a specific direction while greatly weakening the magnetic field on the other side, approximately forming a unilateral magnetic field effect. This magnetic field distribution characteristic allows the power density to be effectively increased in motor applications, because the enhanced magnetic field allows the motor to produce greater torque output in a smaller volume. In some precision equipment such as headphones and other audio devices, the Halbach array can also improve the performance of the sound unit by optimizing the magnetic field, bringing users a better audio experience, such as enhancing the bass effect and improving the fidelity and layering of the sound. wait.

Hangzhou Magnet power Technology Co., Ltd. considers both performance optimization and manufacturing feasibility in the application of Halbach array technology, combining technological innovation with practical applications. Next, let’s explore the unique charm of Halbach arrays.

1. Application fields and advantages of precision Halbach array

1.1Application scenarios and functions

Direct drive motor: In order to solve the problems of larger size and higher cost caused by the increase in the number of pole pairs faced by direct drive motors in market applications, Halbeck array magnetization technology provides a new idea. After adopting this technology, the magnetic flux density on the air gap side is greatly increased, and the magnetic flux on the rotor yoke is reduced, which effectively reduces the weight and inertia of the rotor and improves the rapid response of the system. At the same time, the air gap magnetic flux density is closer to a sine wave, reducing useless harmonic content, reducing cogging torque and torque ripple, and improving motor efficiency.

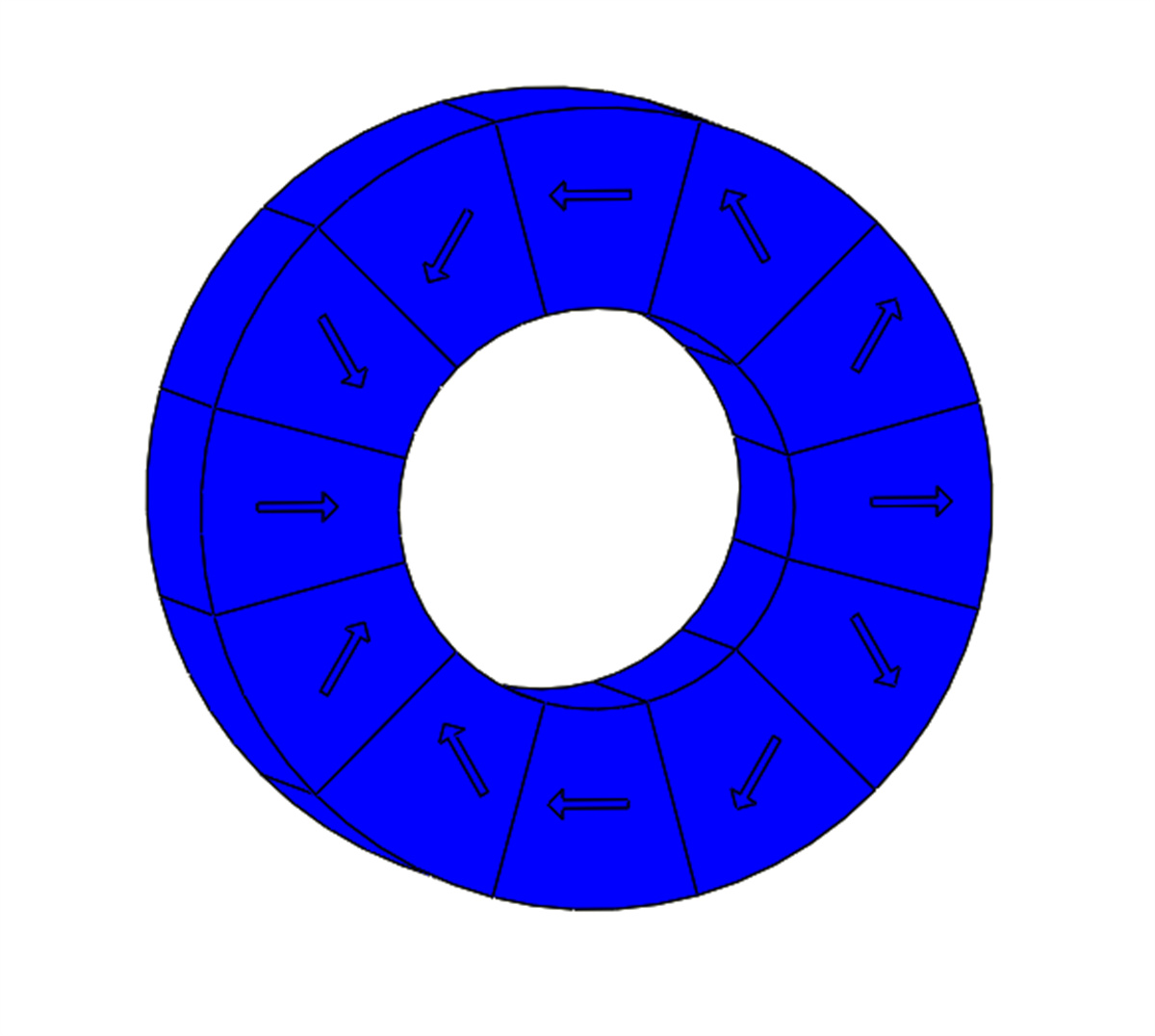

Brushless AC motor: The Halbeck ring array in the brushless AC motor can enhance the magnetic force in one direction and obtain an almost perfect sinusoidal magnetic force distribution. In addition, due to the unidirectional magnetic force distribution, non-ferromagnetic materials can be used as the central axis, which greatly reduces the overall weight and improves efficiency.

Magnetic Resonance Imaging (MRI) equipment: Ring-shaped Halbeck magnets can produce stable magnetic fields in medical imaging equipment, which are used to locate and excite atomic nuclei in detected objects to obtain high-resolution image information.

Particle accelerator: Ring-shaped Halbeck magnets guide and control the movement path of high-energy particles in the particle accelerator, generating a strong magnetic field to change the trajectory and speed of particles, and achieve particle acceleration and focusing.

Ring motor: Ring-shaped Halbach magnets generate different magnetic fields by changing the direction and magnitude of the current to drive the motor to rotate.

Laboratory research: Usually used in physics laboratories to generate stable and uniform magnetic fields for research in magnetism, materials science, etc.

1.2Advantages

Powerful magnetic field: Ring-shaped precision Halbeck magnets adopt a ring magnet design, which allows the magnetic field to be concentrated and focused throughout the entire ring structure. Compared with ordinary magnets, it can produce a higher intensity magnetic field.

Space saving: The ring structure allows the magnetic field to loop in a closed loop path, reducing the space occupied by the magnet, making it more convenient to install and use in some situations.

Uniform distribution of magnetic field: Due to the special design structure, the distribution of magnetic field in the circular path is relatively uniform, and the change in magnetic field intensity is relatively small, which is beneficial to improving the stability of the magnetic field.

Multipolar magnetic field: The design can generate multipolar magnetic fields, and can achieve more complex magnetic field configurations in specific application scenarios, providing greater flexibility and operability for experiments and applications with special needs.

Energy saving and environmental protection: The design materials usually use materials with high energy conversion efficiency. At the same time, through reasonable design and optimization of the magnetic circuit structure, energy waste is reduced and the purpose of energy saving and environmental protection is achieved.

High utilization rate of permanent magnets: As a result of the directional magnetization of Halbach magnets, the operating point of the permanent magnets is higher, generally exceeding 0.9, which improves the utilization rate of permanent magnets.

Strong magnetic performance: Halbach combines the radial and parallel arrangements of magnets, treating the magnetic permeability of the surrounding magnetically permeable materials as infinite to form a unilateral magnetic field.

High power density: The parallel magnetic field and radial magnetic field after the Halbach magnetic ring is decomposed superimpose each other, which greatly increases the magnetic field strength on the other side, which can effectively reduce the size of the motor and increase the power density of the motor. At the same time, the motor made of Halbach array magnets has high performance that conventional permanent magnet synchronous motors cannot achieve, and can provide ultra-high magnetic power density.

2. Technical difficulty of precision Halbach array

Although the Halbach array has many advantages, its technical implementation is also difficult.

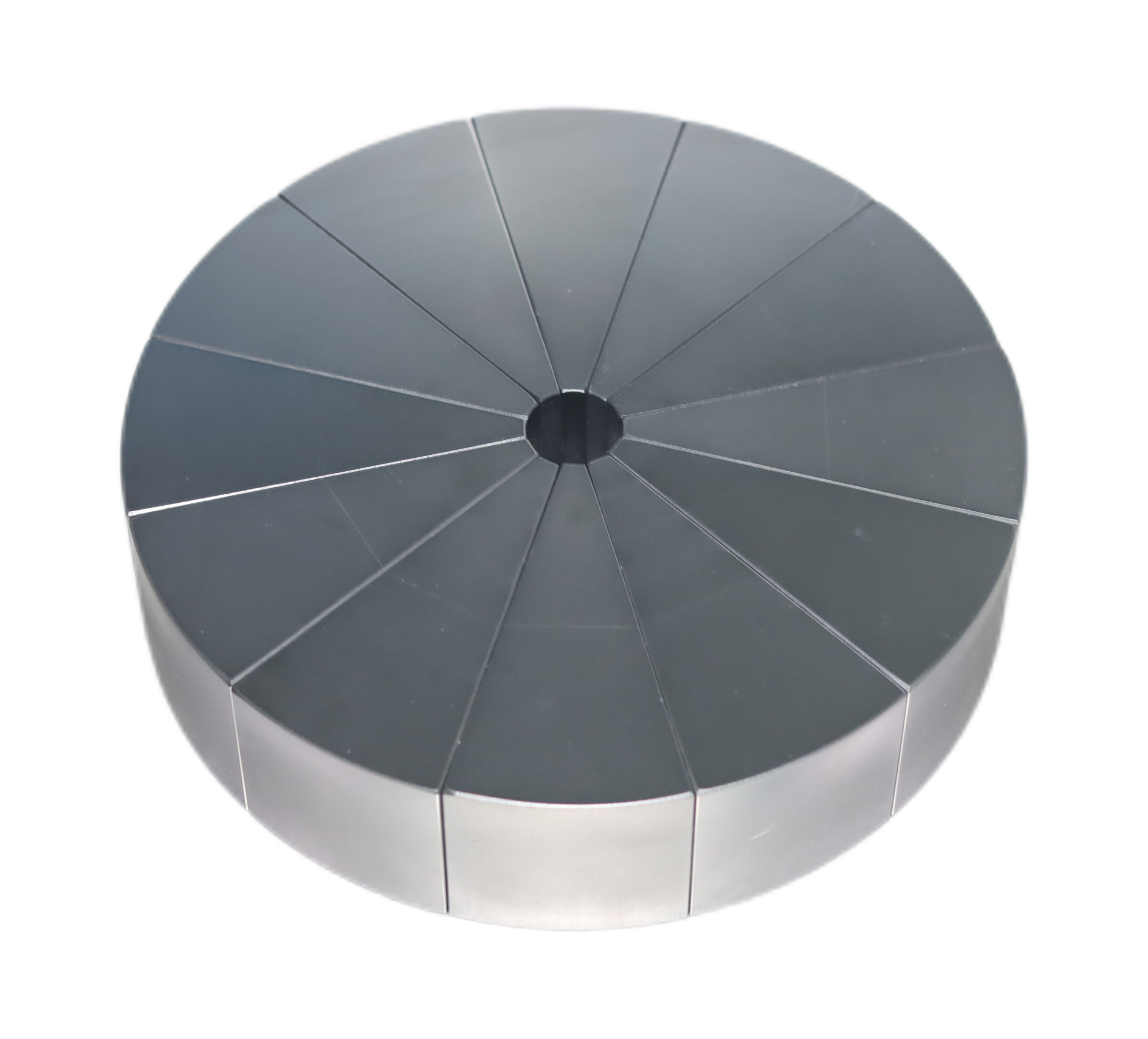

First, during the manufacturing process, the ideal Halbach array permanent magnet structure is that the magnetizing direction of the entire annular permanent magnet changes continuously along the circumferential direction, but this is difficult to achieve in actual manufacturing. In order to balance the contradiction between performance and manufacturing process, companies need to adopt special assembly solutions. For example, the annular permanent magnet is divided into fan-shaped discrete magnet blocks with the same geometric shape, and the different magnetization directions of each magnet block are spliced into a ring, and finally the assembly plan of the stator and rotor is formed. This approach takes into account both performance optimization and manufacturing feasibility, but it also increases manufacturing complexity.

Secondly, the assembly accuracy of Halbach array is required to be high. Taking the precision Halbach array assembly used for magnetic levitation motion tables as an example, assembly is very difficult due to the interaction between magnets. The traditional assembly process is cumbersome and can easily cause problems such as low flatness and large gaps in the magnet array. In order to solve these problems, the new assembly method uses beading as an auxiliary tool. The main magnet with the upward force direction of the main magnet is first adsorbed on the bead and then positioned on the bottom plate, which improves the assembly efficiency and tightness of the magnet array. and the positional accuracy of the magnets and the linearity and flatness of the magnet array.

In addition, the magnetization technology of the Halbach array is also difficult. Under traditional technology, various types of Halbach arrays are mostly pre-magnetized and then assembled when used. However, due to the changeable force directions between the permanent magnets of the Halbach permanent magnet array and the high assembly accuracy, the permanent magnets after pre-magnetization are Magnets often require special molds during assembly. Although the overall magnetization technology has the advantages of improving magnetization efficiency, reducing energy costs and reducing assembly risks, it is still in the exploratory stage due to the technical difficulty. The mainstream of the market is still produced by pre-magnetization and then assembly.

3. Advantages of Hangzhou Magnetic Technology’s precision Halbach array

3.1. High power density

Hangzhou Magnet power Technology’s precision Halbach array has significant advantages in power density. It superimposes the parallel magnetic field and the radial magnetic field, greatly increasing the magnetic field strength on the other side. This feature can effectively reduce the size of the motor and increase the power density. Compared with the traditional permanent magnet motor architecture, Hangzhou Magnet Technology uses precision Halbach array technology to achieve miniaturization of the motor at the same output power, saving space for various application scenarios and improving energy utilization efficiency.

3.2. The stator and rotor do not need chute

In traditional permanent magnet motors, due to the inevitable presence of harmonics in the air gap magnetic field, it is usually necessary to adopt ramps on the stator and rotor structures to weaken their influence. The precision Halbach array air-gap magnetic field of Hangzhou Magnet power Technology has a high degree of sinusoidal magnetic field distribution and small harmonic content. This eliminates the need for skews in the stator and rotor, which not only simplifies the motor structure, reduces manufacturing difficulty and cost, but also improves the operating stability and reliability of the motor.

3.3. The rotor can be made of non-core materials

The self-shielding effect of the precision Halbach array generates a single-sided magnetic field, which provides greater space for the selection of rotor materials. Hangzhou Magnet Technology makes full use of this advantage and can choose non-core materials as the rotor material, which reduces the moment of inertia and improves the motor’s rapid response performance. This is particularly important for application scenarios that require frequent starts and stops and rapid speed adjustment, such as automated production lines, robots and other fields.

3.4. High utilization rate of permanent magnets

The precision Halbach array of Hangzhou Magnet power Technology uses directional magnetization to achieve a higher operating point, generally exceeding 0.9, which greatly improves the utilization rate of permanent magnets. This means that with the same amount of magnets, a stronger magnetic field can be generated and the output performance of the motor can be improved. At the same time, it also reduces dependence on rare resources, reduces costs, and meets the requirements of sustainable development.

3.5. Concentrated winding can be used

Due to the high sinusoidal distribution of the magnetic field of the precision Halbeck array and the small influence of the harmonic magnetic field, Hangzhou Magnet power Technology can use concentrated windings. Concentrated windings have higher efficiency and lower losses than the distributed windings used in traditional permanent magnet motors. In addition, concentrated winding can also reduce the size and weight of the motor, increase the power density, and provide more possibilities for miniaturization and lightweighting of the motor.

4. R&D team

Hangzhou Magnet power Technology has a professional and efficient R&D team, which provides strong support for the company in the application and innovation of precision Halbach array technology.

Team members come from different professional fields and have rich technical background and experience. Some of them have doctorates and master’s degrees in electrical engineering, magnetism, materials science and other related majors, and have more than 20 years of industry experience in motor research and development, magnet design, manufacturing processes and other fields. Years of experience enable them to quickly understand and solve complex technical problems. In the future, the team will continue to explore different application fields and new development directions of precision Halbach array technology.

Post time: Nov-26-2024