In today’s society, permanent magnet components play an indispensable and key role in many fields. From the drive motor of electric vehicles to the precision sensors in industrial automation equipment, from the key components of medical equipment to the small motors of consumer electronics, they are closely related to people’s lives. The quality and performance of permanent magnet components directly affect the quality and competitiveness of the entire product. Therefore, for enterprises, finding a qualified permanent magnet component supplier is not only related to the performance and quality of the product, but also affects the company’s reputation in the market and sustainable development capabilities.

Characteristics of qualified suppliers

(I) Strong technical strength

An excellent permanent magnet component supplier must have advanced production technology and strong R&D capabilities. In the research and development and production process of permanent magnet materials, complex physical and chemical knowledge, as well as high-precision processing technology, are required. They can continuously innovate, develop new permanent magnet materials or improve existing production processes according to market demand and technological development trends, and meet customers’ requirements for high performance and diversification of permanent magnet components.

(II) Strict quality control

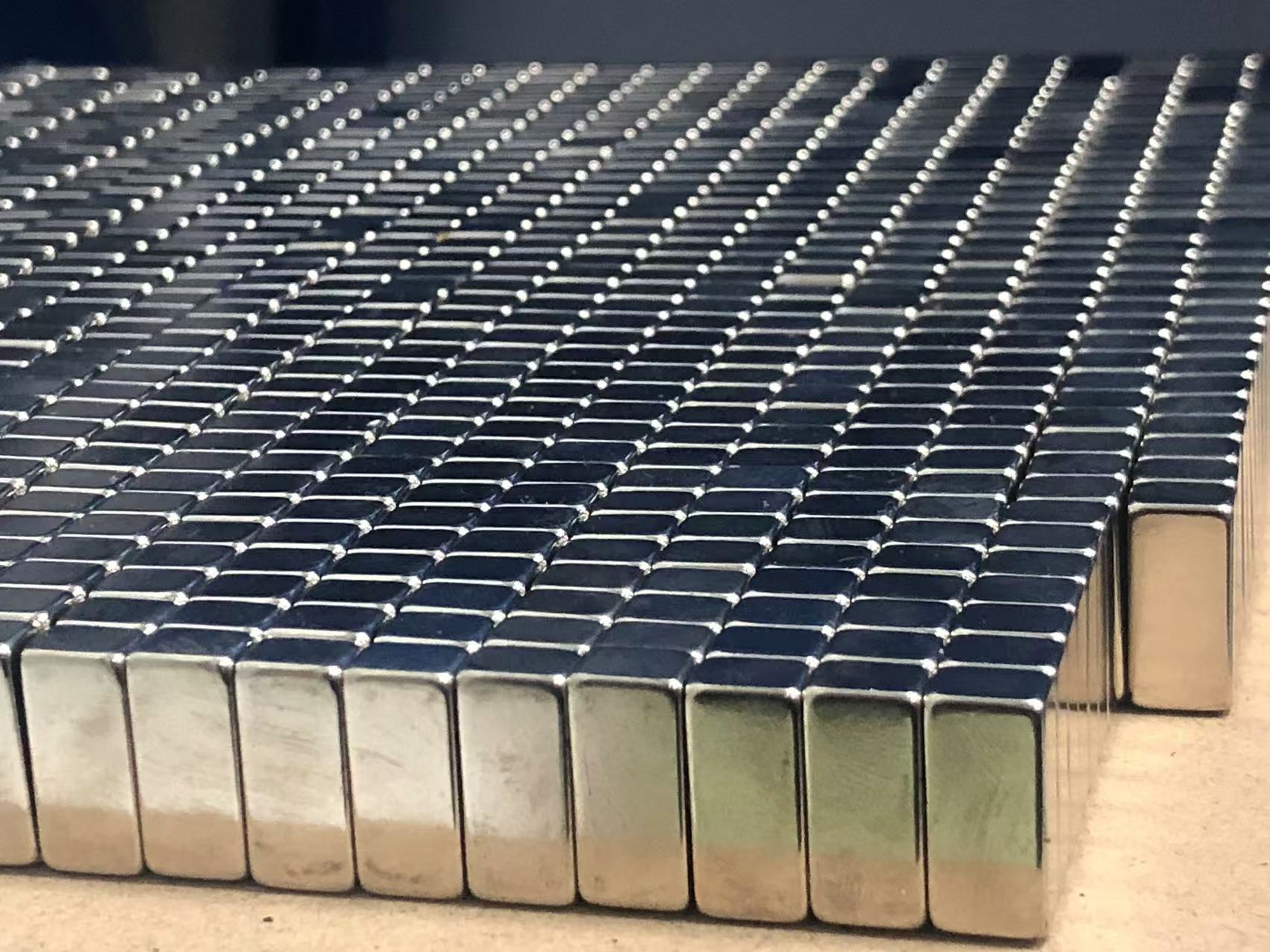

Quality is the lifeline of permanent magnet components, and qualified suppliers will establish a complete quality control system. Starting from the procurement of raw materials, they will conduct strict inspections on each batch of raw materials such as rare earth to ensure that their purity and quality meet production requirements. During the production process, through advanced testing equipment and strict process flow monitoring, the dimensional accuracy, magnetic properties, surface quality and other dimensions of permanent magnet components are tested in real time. Each production link has corresponding quality standards and inspection procedures. Only products that have passed strict inspections will be allowed to enter the market to ensure that the permanent magnet components delivered to customers fully meet the standards.

(III) Good reputation

In a highly competitive market environment, reputation is an important business card for an enterprise. Qualified permanent magnet component suppliers have a high degree of recognition in the market, thanks to their long-term high-quality service and high-quality product supply to customers. From communication with customers, order processing to after-sales guarantee, they can be professional, efficient and thoughtful. Customers have a good evaluation of them, whether it is the stability of product quality, the timeliness of delivery or the professionalism of technical support, they can win praise from customers. Through word of mouth and long-term accumulation in the industry, these suppliers have established a good brand image in the market and become the preferred partners of many companies.

(IV) Stable production capacity supply

For enterprises, whether suppliers can supply on time and in quantity is crucial. Qualified permanent magnet component suppliers have stable production capacity supply capabilities. They are equipped with advanced and sufficient production equipment, have reasonable production planning and efficient production management teams. Whether it is to cope with daily order needs, or in the peak season of the market or when encountering urgent large-scale orders, they can ensure a stable production rhythm and ensure timely delivery.

Methods for selecting qualified suppliers

(I) Understand the types of permanent magnet materials

There are many types of permanent magnet materials, and different application scenarios require permanent magnet materials with different characteristics. Common permanent magnet materials include neodymium iron boron and samarium cobalt. Neodymium iron boron permanent magnet materials have the characteristics of high magnetic energy product and high cost performance. They are widely used in fields such as motors with high magnetic properties requirements, but their corrosion resistance is relatively weak and the operating temperature range is limited. Samarium cobalt permanent magnet materials have good high temperature resistance and corrosion resistance, and are suitable for applications in high temperature and harsh environments. When selecting suppliers, enterprises need to choose suppliers who are good at producing the corresponding types of permanent magnet materials according to the specific use environment and performance requirements of their own products.

(II) Check the qualification certification

Qualification certification is one of the important bases for measuring whether the supplier is qualified. The supplier should have relevant industry certification, such as ISO9001 quality management system certification, which indicates that it follows the international standard quality management system in the production management process and can effectively ensure the stability of product quality. At the same time, you can also check whether the supplier has other specific industry or international standard certifications, such as professional certification for the application of permanent magnet components in certain specific fields.

(III) Inspect production capacity

Inspecting the supplier’s production capacity is a key link in the selection process. Enterprises can understand the supplier’s production line through field visits, including the degree of advancement of production equipment and the level of automation. Advanced production equipment can often ensure higher production accuracy and efficiency. At the same time, attention should be paid to the maintenance of equipment. Good equipment maintenance can reduce downtime and ensure the continuity of production. In addition, it is also very important to understand the supplier’s process level. By asking about the details of the production process and checking the process documents, evaluate whether its process is scientific and reasonable, and whether it has unique process advantages to ensure product quality and performance.

(IV) Evaluate the quality control system

The quality control system is the core of ensuring the quality of permanent magnet components. Enterprises should have a deep understanding of the supplier’s quality control measures throughout the process from raw materials to finished products. In the raw material procurement process, ask suppliers how to evaluate and select raw material suppliers and how to ensure the stability of raw material quality. In the production process, check whether there is a complete online detection and process control mechanism, such as whether to set up quality inspection points in key production processes, and monitor and adjust the key performance indicators of the product in real time. For finished products, understand the standards and processes of their final inspection, including sampling methods, inspection items, and qualification criteria, to ensure that every permanent magnet component shipped out of the factory can meet the quality requirements.

(V) Refer to market reputation

Market reputation is a true reflection of the supplier’s past performance. Enterprises can obtain market reputation information of suppliers through various channels. Communicate with companies in the same industry to find out whether they have cooperated with the supplier and what their experience is during the cooperation process, including evaluations of product quality, delivery time, after-sales service, etc. You can also search for relevant information about the supplier on the online platform to view customer evaluations and feedback. In addition, when participating in industry exhibitions, seminars and other activities, you can also ask industry experts and industry insiders about the reputation of the supplier and judge the reliability of the supplier based on comprehensive information from various aspects.

Selecting a qualified permanent magnet component supplier has a far-reaching positive impact on the development of the entire industry. High-quality suppliers can provide enterprises with high-quality permanent magnet components, thereby improving the performance and quality of enterprise products and enhancing the competitiveness of enterprises in the market. This will further promote the development of various application fields, such as promoting the improvement of the driving range of the electric vehicle industry, improving the operating efficiency of industrial automation equipment, and improving the diagnostic accuracy of medical equipment. With the continuous advancement of science and technology, we expect permanent magnet component suppliers to continue to improve their own technical level and service quality, grow together with downstream enterprises, promote the entire industry chain to develop in a more efficient and high-quality direction, and make greater contributions to the progress of the global science and technology industry.

Post time: Nov-01-2024