Introduction to Strong Magnetic Materials

Strong magnetic materials, especially permanent magnetic materials such as neodymium iron boron (NdFeB) and samarium cobalt (SmCo), have been widely used in modern industry due to their strong magnetic field strength and excellent performance. From motors to medical devices, from consumer electronics to aerospace, these materials play an important role. Although strong magnetic materials are used in many fields, their potential dangers cannot be ignored. Let us learn how strong magnetic materials are made, better understand the potential risks, and better prevent them.

How strong magnetic materials are born

1. Raw material preparation: The first step in producing strong magnetic materials is to prepare raw materials. For NdFeB, the main raw materials include neodymium, iron, boron and other trace elements such as dysprosium and praseodymium. The raw materials need to be strictly screened and processed to ensure that the purity and composition ratio meet the requirements.

2. Melting: The prepared raw materials are placed in a vacuum induction furnace for melting to form an alloy. In this process, temperature control is very critical and usually needs to be carried out at a high temperature of more than 1000°C. The smelted alloy liquid will be poured into a mold to cool and form an ingot.

3. Crushing and grinding: The cooled ingot needs to be broken into small pieces by a crusher and then further ground into fine powder by a ball mill. The particle size of the fine powder directly affects the quality of the subsequent process, so this step is very important.

4. Orientation pressing: The fine powder is loaded into a mold and then oriented and pressed under the action of a strong magnetic field. This ensures that the direction of the magnetic powder particles is consistent, thereby improving the magnetic properties of the final product. The product after oriented pressing is called “green body”.

5. Sintering: The green body is placed in a sintering furnace and sintered at high temperature (about 1000°C-1100°C) to solidify and form a dense magnet. During the sintering process, the material undergoes complex physical and chemical changes, and finally forms a finished product with high magnetic properties.

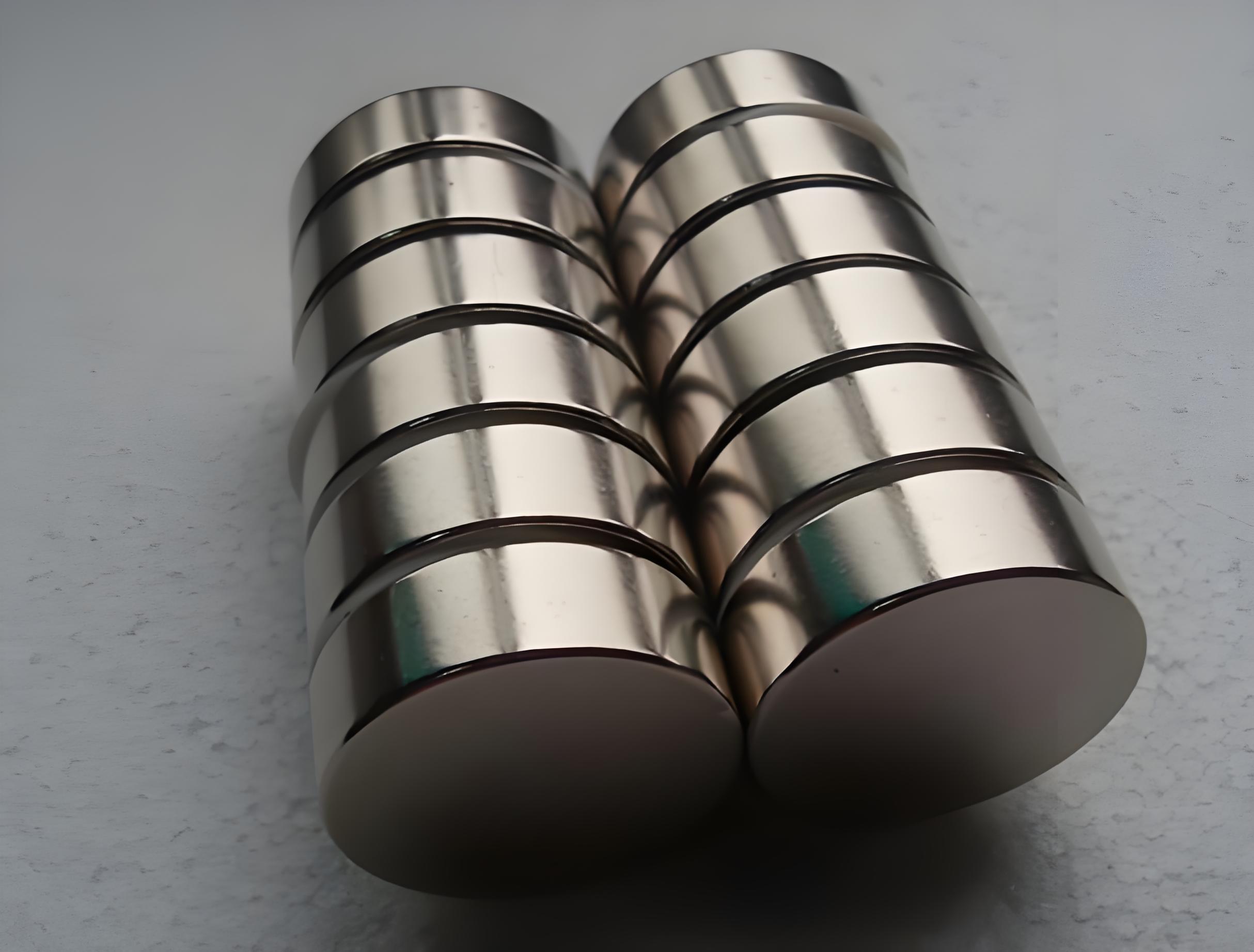

6. Processing and surface treatment: The sintered magnet also needs to be cut, polished and other mechanical processing to achieve the required shape and size. In order to prevent the magnet from oxidation or corrosion during use, a protective layer such as nickel, zinc or epoxy resin is usually coated on its surface.

7. Magnetization: The last step is to magnetize the magnet to give it the required magnetic properties. Magnetization is usually carried out in a special magnetization equipment, using a strong magnetic field to make the magnetic domains in the magnet consistent.

The harm of strong magnetism

The lethality of strong magnetic materials is mainly reflected in the following aspects:

1. Impact on electronic devices: Strong magnetic materials can interfere with the operation of electronic devices, especially those that rely on magnetic sensors. For example, mobile phones, computer hard drives, credit cards, etc. may be affected by strong magnetic fields, resulting in data loss or equipment damage.

2. Impact on the human body: Although strong magnetic materials do not pose a direct fatal threat to the human body, they may cause local pain or discomfort if swallowed or contacted with the skin. In addition, strong magnetic materials may also attract nearby metal objects and cause accidental injuries.

3. Impact on other magnetic materials: Strong magnetic materials can attract and move other magnetic materials, which may cause heavy objects to fall or equipment to be damaged if not handled properly. Therefore, when using strong magnetic materials, appropriate safety measures must be taken to avoid unnecessary risks.

4. Impact on mechanical equipment: In some cases, strong magnetic materials may adsorb metal parts in mechanical equipment, causing equipment failure or shutdown. This effect is particularly serious in precision instruments and medical devices.

How to prevent the effects of strong magnetism

1. Keep your distance: Keep strong magnetic materials away from electronic devices, credit cards and other sensitive items.

2. Protective measures: Wear appropriate protective equipment when handling strong magnetic materials and avoid direct contact with the skin.

3. Education and warnings: Educate children not to play with strong magnetic toys and make sure they understand the potential dangers.

4. Professional guidance: In medical environments, ensure that patients and staff understand the safety regulations for strong magnetic materials and take appropriate protective measures.

5. Storage and transportation: Strong magnetic materials should be stored in special containers and properly protected during transportation to prevent contact with other items.

The production process of strong magnetic materials is a complex and delicate process involving multiple steps and professional technical means. Understanding its production process helps us better understand and apply these materials. At the same time, we also need to be aware of the potential dangers of strong magnetic materials and take effective protective measures to ensure our safety.

Post time: Oct-25-2024