SmCo Magnet

Short Description:

Magnet Power team has been developing SmCo magnets for many years and has a deep understanding of materials science and engineering technology. This enables us to design the most suitable SmCo magnets and create value for customers.

The main samarium-cobalt products developed, produced by Magnet Power are shown as follows:

Magnets 1: SmCo5(1:5 18-22)

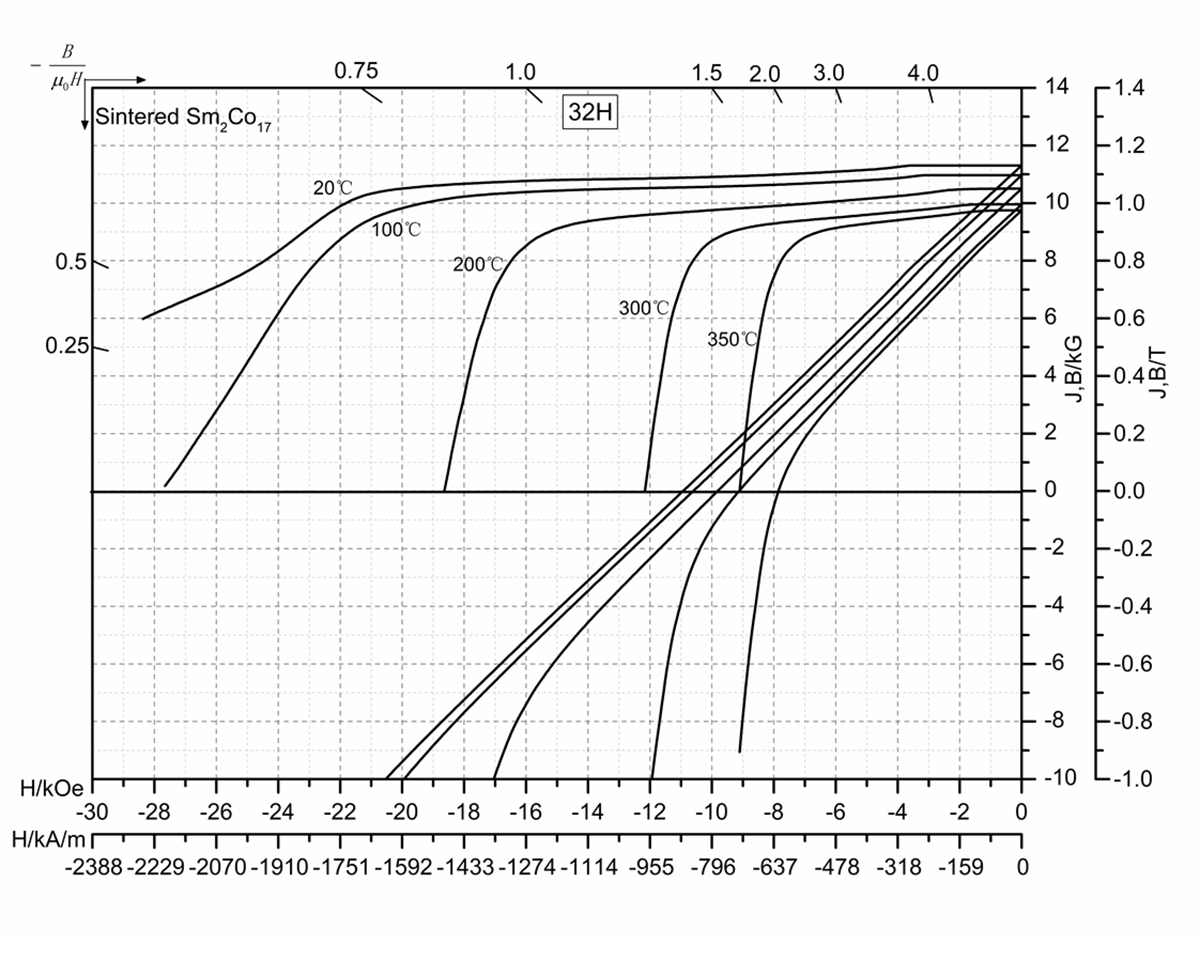

Magnets 2: Sm2Co17(H series Sm2Co17 )

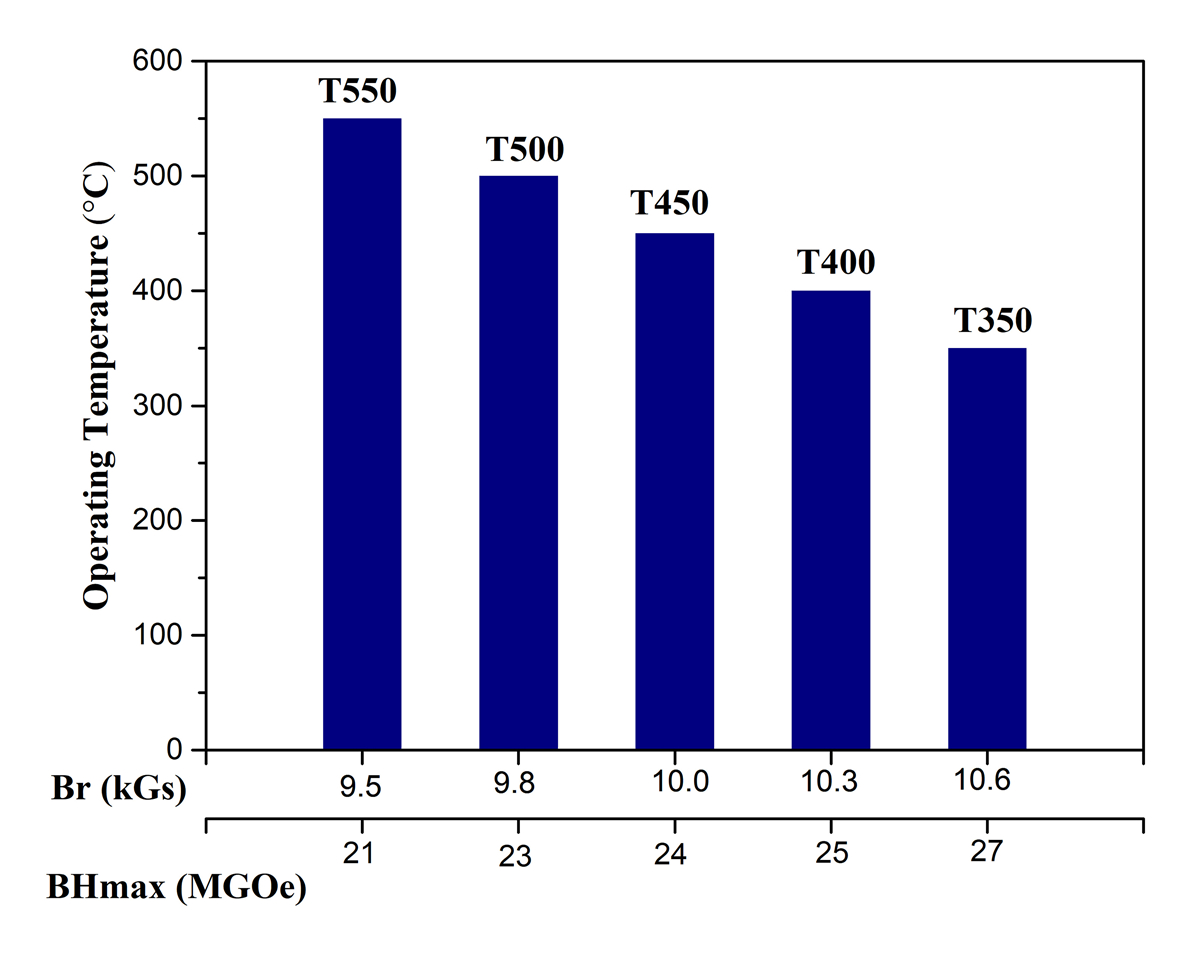

Magnets 3: High temperature resistance Sm2Co17(T series Sm2Co17, T350-T550)

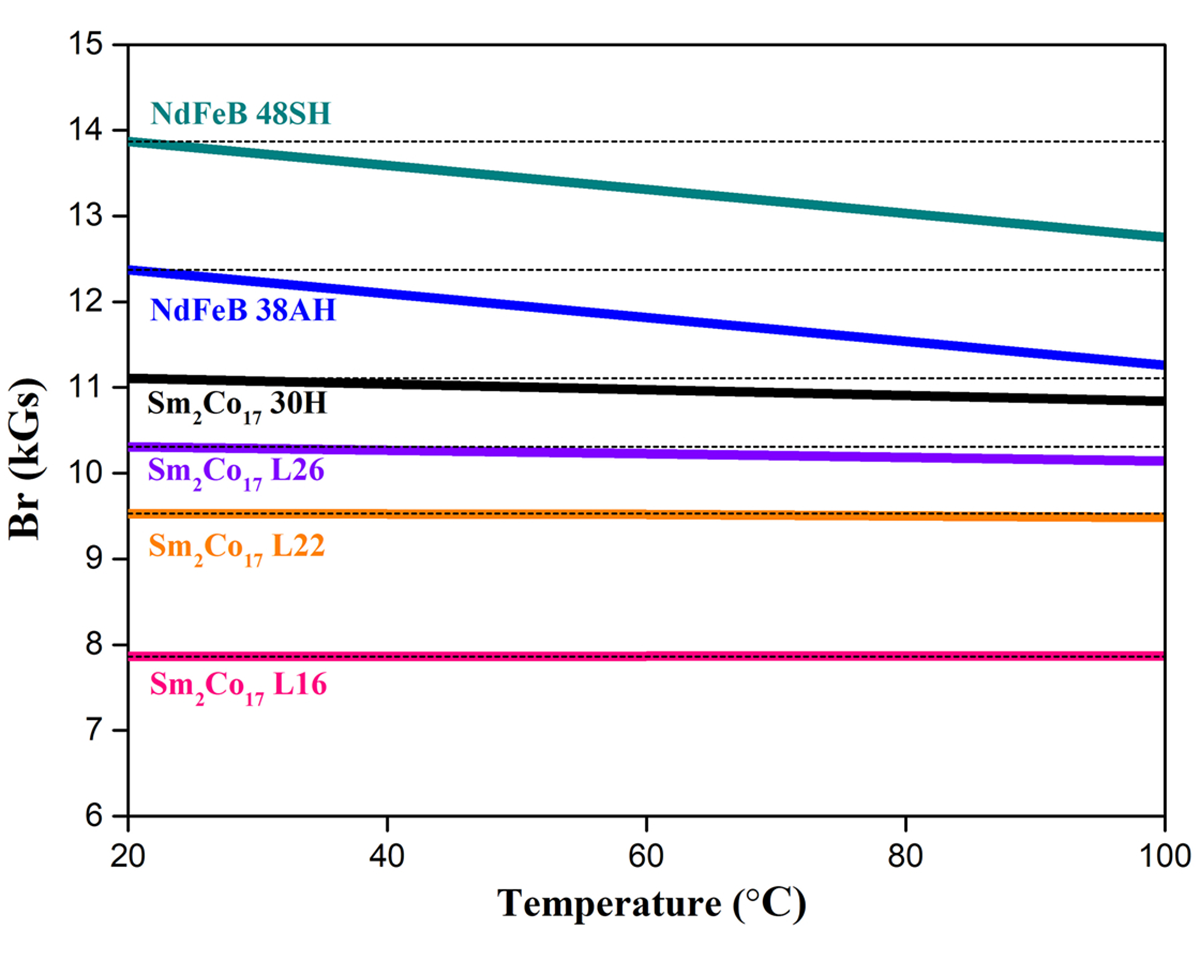

Magnets 4: Temperature compensated Sm2Co17(L series Sm2Co17, L16-L26)

The samarium cobalt products of Magnet Power have been widely used in:

High Speed Motors (10,000 rpm+)

Medical Devices and Equipments,

Rail Transit

Communication

Scientific research

H series Sm2Co17

T series Sm2Co17

L series Sm2Co17

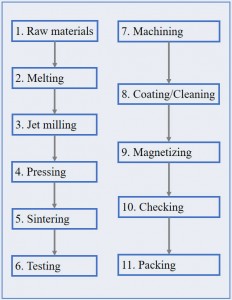

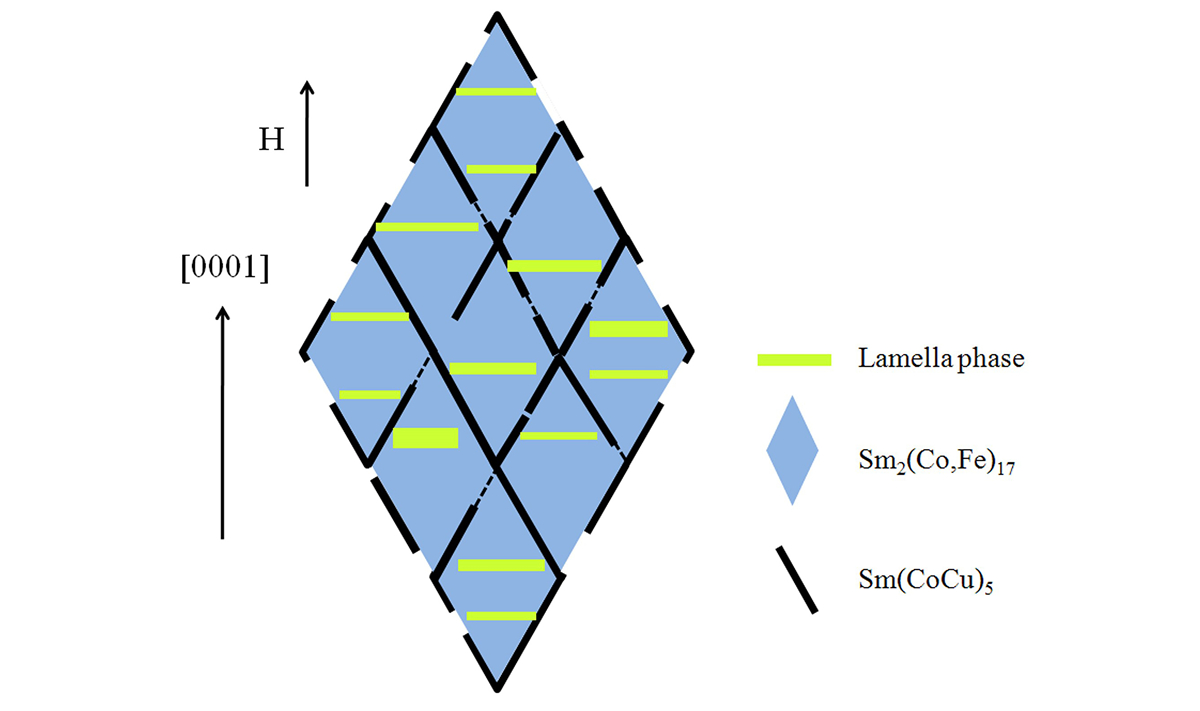

The composition and microstructure control are the key points of samarium cobalt magnet production and determine the magnetic properties. Because of non-standard shape, tolerance and appearance of samarium cobalt magnets are also important.

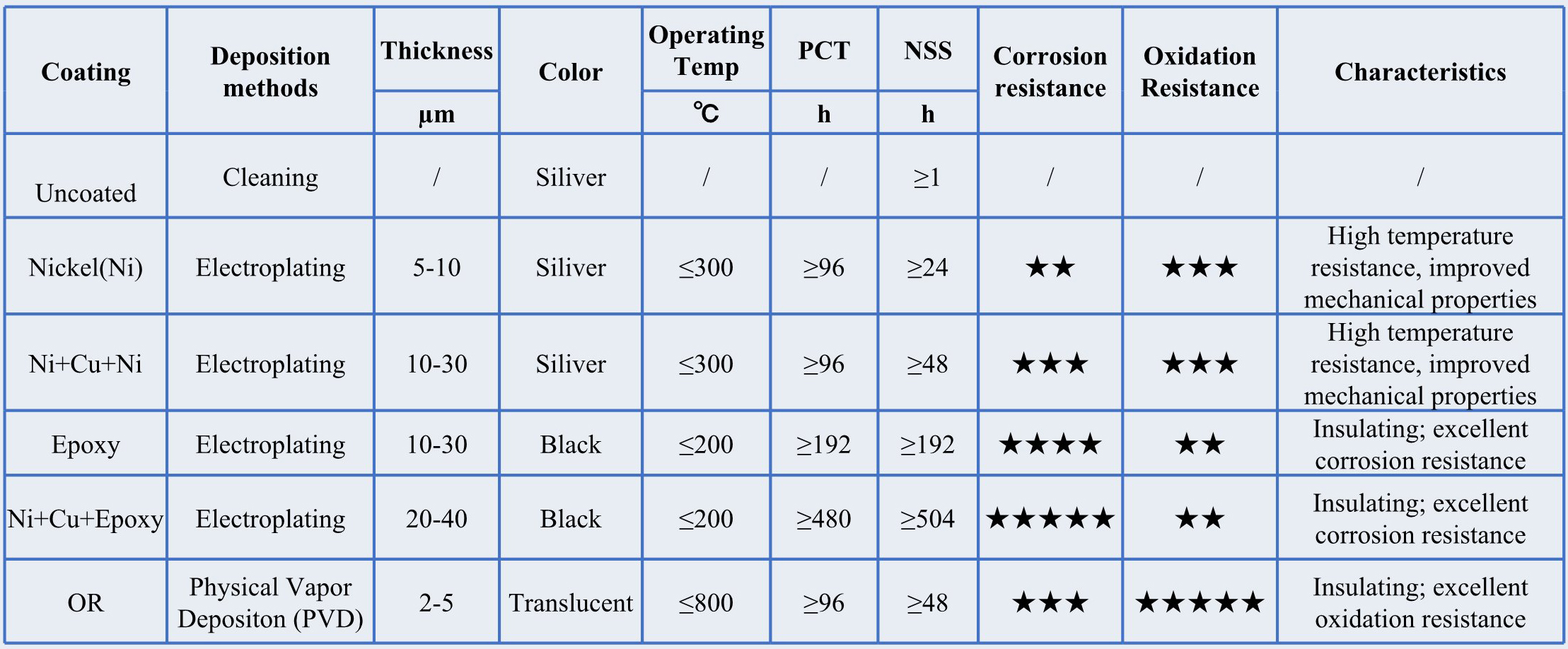

● Ni-based coating can effectively improve the bending strength of Sm2Co17 ~50%

● Ni-based coatings can be applied up to 350℃ to improve surface appearance and long-term stability

● Epoxy-based coating can be applied up to 200 ℃ (short time) to enhance mechanical properties, corrosion resistance, and to decrease eddy-current and to suppress temperature rise.

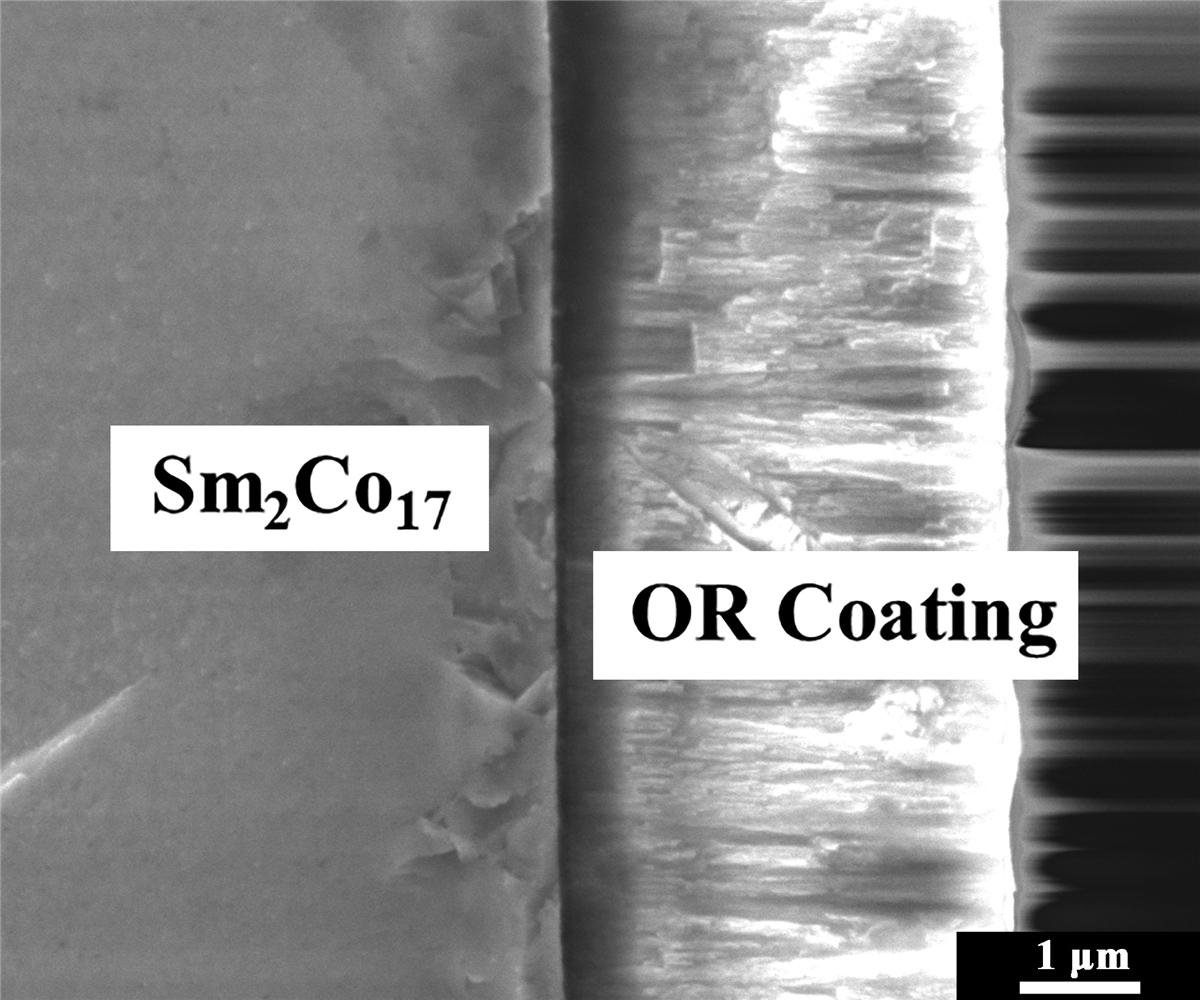

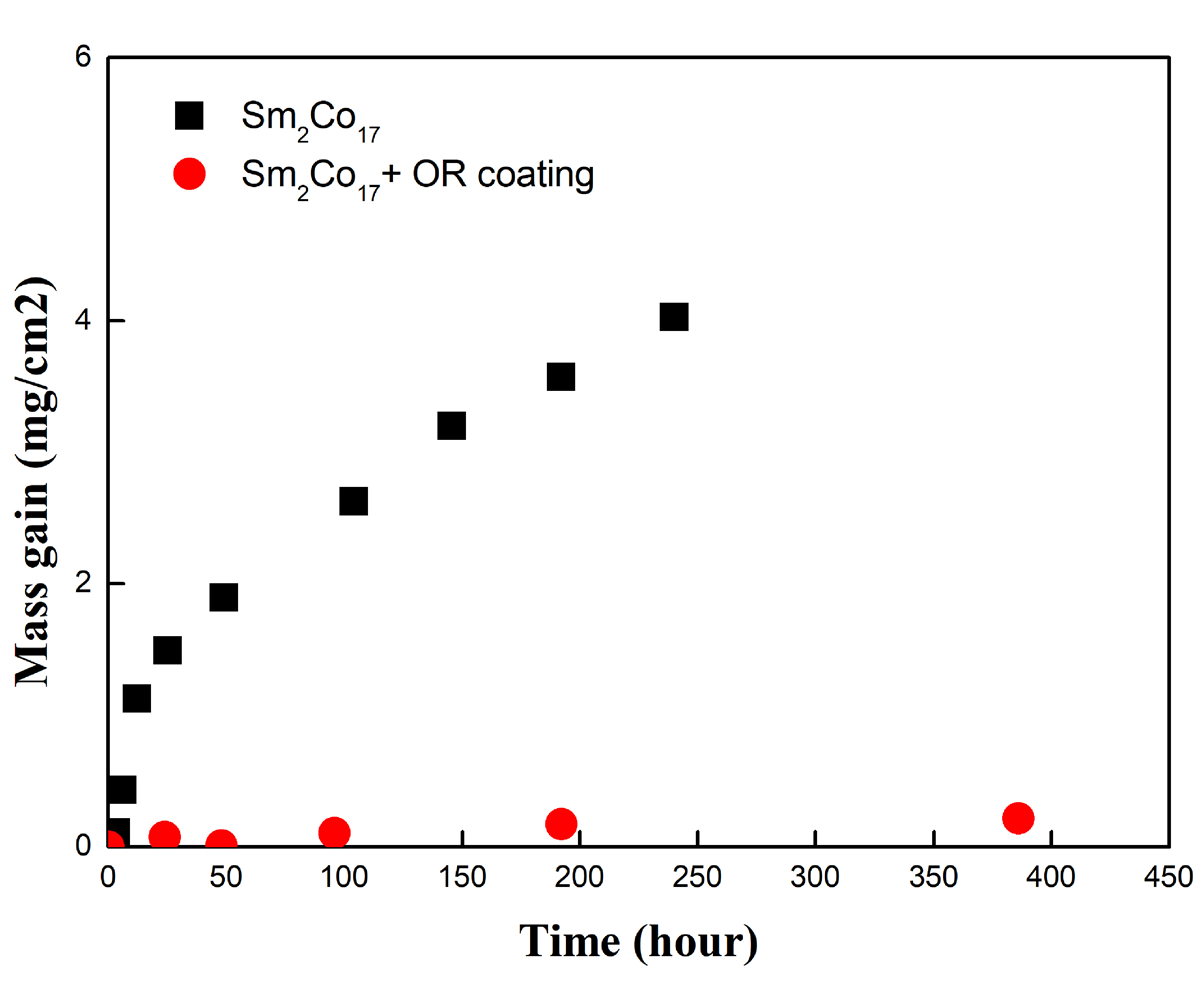

● At ultra high temperature 500℃ in air, degradation layer will affect magnetic properties. OR coating can effectively improve the long-term stability of SmCo at 500℃

● Due to its excellent insulation properties, the OR coating can decrease eddy-current and suppress temperature rise.

● Environmentally friendly.