Dhowaan, sida tignoolajiyadu u horumarayso soo noqnoqoshada sare iyo xawaaraha sare, luminta hadda jirta ee magnets waxay noqotay dhibaato weyn. Gaar ahaan kuwaNeodymium Iron Boron(NdFeB) iyoSamarium Cobalt(SmCo) magnets, ayaa si fudud u saameeya heerkulka. Khasaarada hadda jirta waxay noqotay dhibaato weyn.

Dhaqdhaqaaqyada qallafsan ayaa had iyo jeer keena kulayl jiilka, ka dibna hoos u dhaca waxqabadka matoorada, koronto-dhaliyeyaasha, iyo dareemayaasha. Tignoolajiyada hadda jirta ee ka-hortagga ah ee magnets-ku waxay inta badan xakamaysaa jiilka hadda jira ama waxay xakamaysaa dhaqdhaqaaqa hadda la kiciyay.

"Awoodda Magnet" waxaa la sameeyay tignoolajiyada ka-hortagga-eddy-current ee NdFeB iyo magnets SmCo.

The Eddy Currents

Xawaaraha Eddy waxa lagu abuuraa walxo wax dhaqaajiya kuwaas oo ku jira goob koronto oo beddelanaysa ama bedalka magnetka. Sida uu qabo sharciga Faraday, dhulalka magnet-ka ah ee is bedbeddela waxa ay dhaliyaan koronto, taas beddelkeeda. Warshadaha, mabda'a this waxaa loo isticmaalaa dhalaalidda biraha. Iyada oo la adeegsanayo soo-celinta soo noqnoqoshada dhexdhexaadka ah, walxaha korantada ee ku-meel-gaadhka ah, sida Fe iyo biraha kale, ayaa loo kiciyaa si ay u dhaliyaan kulayl, ugu dambeyntiina walxaha adag waa la dhalaaliyaa.

Iska caabin ah magnets ndFeB, SmCo magnets ama Alnico magnets had iyo jeer waa mid aad u hooseeya. Waxaa lagu muujiyey shaxda 1. Sidaa darteed, haddii magnets-yadani ay ku shaqeeyaan aaladaha korantada, isdhexgalka ka dhexeeya qulqulka magnetic iyo qaybaha korantada ayaa si fudud u dhaliya qulqulka qulqulka.

Shaxda1 Iska caabinta magnets ndFeB, magnets SmCo ama magnets Alnico

| Magnets | Rdareen (mΩ·cm) |

| Alnico | 0.03-0.04 |

| SmCo | 0.05-0.06 |

| NdFeB | 0.09-0.10 |

Marka loo eego sharciga Lenz, qulqulka Eddy ee ka dhasha NdFeB iyo magnets SmCo, waxay keenaysaa saameyn aan loo baahnayn oo dhowr ah:

● Tamarta Luminta: Sababo la xiriira qulqulka qulqulka, qayb ka mid ah tamarta birlabeedka ayaa loo beddelaa kulayl, taas oo yaraynaysa waxtarka aaladda. Tusaale ahaan, luminta birta iyo luminta naxaasta ee ay ugu wacan tahay qulqulka qulqulka ayaa ah qodobka ugu muhiimsan ee waxtarka matoorada. Marka la eego hoos u dhigista qiiqa kaarboonka, hagaajinta waxtarka matoorada ayaa aad muhiim u ah.

Dhalinta kulaylka iyo Demagnetization: Labada magnets ee NdFeB iyo SmCo waxay leeyihiin heerkulka ugu sarreeya ee hawlgalka, kaas oo ah qiyaasta muhiimka ah ee magnets joogto ah. Kulaylka ka dhasha luminta hadda jirta waxay sababtaa heerkulka magnets-ka kor u kaca. Marka heerkulka ugu sarreeya ee hawlgalka la dhaafo, demagnetization ayaa dhacaya, taas oo ugu dambeyntii horseedi doonta hoos u dhaca shaqada qalabka ama dhibaatooyinka waxqabadka culus.

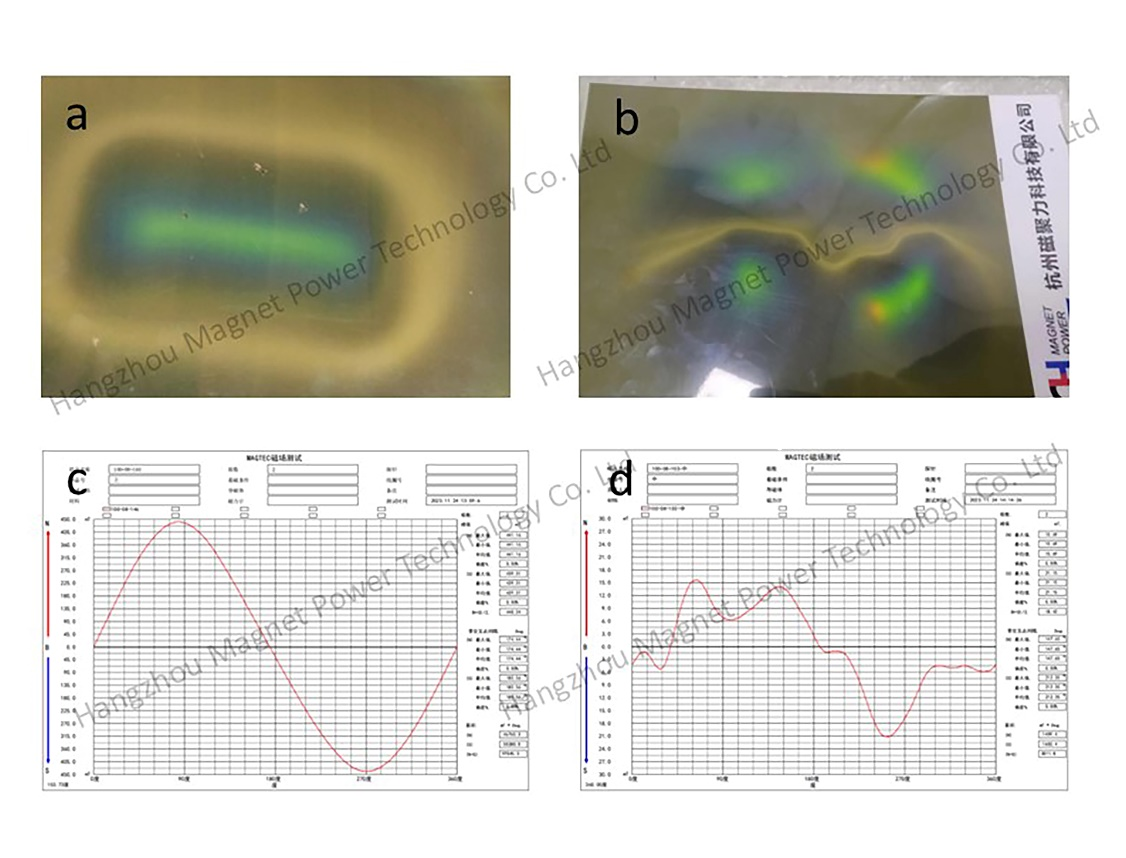

Gaar ahaan ka dib markii la horumariyo matoorrada xawaaraha sare leh, sida matoorada xajinta magnetic iyo matoorrada hawo-qaadista, dhibaatada demagnetization ee rotors ayaa noqday mid caan ah. Jaantuska 1 wuxuu muujinayaa rotor-ka matoorka hawada sidda oo xawligiisu yahay30,000RPM Heerkulku wuxuu ugu dambeyntii kacay qiyaastii500°C, taasoo keentay demagnetization ee magnets.

Jaantuska1. a iyo c waa jaantuska goobta magnetic iyo qaybinta rotor caadiga ah, siday u kala horreeyaan.

b iyo d waa jaantuska goobta magnetic iyo qaybinta rotor demagnetized, siday u kala horreeyaan.

Intaa waxaa dheer, magnets NdFeB waxay leeyihiin heerkulka Curie hooseeya (~ 320 ° C), taas oo ka dhigaysa demagnetization. Heerkulka curie ee magnets-ka SmCo, wuxuu u dhexeeyaa 750-820°C. NdFeB way fududahay in lagu saameeyo qulqulka hadda marka loo eego SmCo.

Anti-Eddy Technology hadda

Dhowr habab ayaa la sameeyay si loo yareeyo qulqulka qulqulka ee NdFeB iyo SmCo magnets. Habkan ugu horreeya waa in la beddelo halabuurka iyo qaab-dhismeedka magnets si kor loogu qaado caabbinta. Habka labaad oo had iyo jeer loo isticmaalo injineernimada si loo carqaladeeyo samaynta wareegyada hadda jira ee waaweyn.

1. Kor u qaadida iska caabinta magnets

Gabay et.al ayaa lagu daray CaF2, B2O3 in magnets SmCo si loo hagaajiyo iska caabin ah, kaas oo la wanaajiyey laga bilaabo 130 μΩ cm ilaa 640 μΩ cm. Si kastaba ha ahaatee, (BH) ugu badnaan iyo Br ayaa si weyn hoos ugu dhacay.

2. Lamination of Magnets

Laminating the magnets, waa habka ugu waxtarka badan ee injineernimada.

Magnet-ka ayaa la jarjaray lakabyo khafiif ah ka dibna la isku dhejiyay. Xidhiidhka u dhexeeya laba qaybood oo magnets ah ayaa ah koollada dahaarka. Dariiqa korantada ee qulqulka qulqulka ayaa go'an. Tignoolajiyadan ayaa si weyn loogu isticmaalaa matoorada xawaaraha sare leh iyo kuwa dhaliya. "Awoodda Magnet" ayaa la sameeyay tignoolajiyada badan si loo hagaajiyo iska caabinta magnets. https://www.magnetpower-tech.com/high-electrical-impedance-eddy-current-series-product/

Halbeegga ugu horreeya ee muhiimka ah waa iska-caabbinta. Iska caabbinta NdFeB iyo magnets-ka SmCo ee la dahaadhay ee ay soo saartay "Awoodda Magnet" waxay ka sarreysaa 2 MΩ·cm. Magnet-yadani waxay si weyn u joojin karaan dhaqdhaqaaqa hadda ee magnetka ka dibna waxay xakameeyaan kulaylka.

Halbeegga labaad waa dhumucda xabagta u dhaxaysa qaybo birlabeedka. Haddii dhumucda lakabka koollada uu aad u sarreeyo, waxay keeni doontaa in mugga magnetka uu hoos u dhaco, taasoo keentay hoos u dhaca guud ahaan qulqulka magnetic. "Awoodda Magnet" waxay soo saari kartaa birlab la dhejiyay oo leh dhumucda lakabka koollada ee 0.05mm.

3. Ku dahaadhida Walxaha adkeysi-sare leh

Dahaarka dahaarka ah ayaa had iyo jeer lagu dabaqaa dusha sare ee magnets si kor loogu qaado iska caabinta magnets. Dahaarkani waxay u shaqeeyaan sidii caqabado, si loo yareeyo qulqulka qulqulka qulqulka ee dusha sare ee magnetka. Sida epoxy ama parylene, ee dahaarka dhoobada ayaa had iyo jeer la isticmaalaa.

Faa'iidooyinka Tignoolajiyada Hadda Joogta ee Anti-Eddy

Tiknoolajiyada hadda jirta ee ka-hortagga waa lagama maarmaan in lagu dabaqo codsiyo badan oo leh NdFeB iyo magnets SmCo. Oo ay ku jiraan:

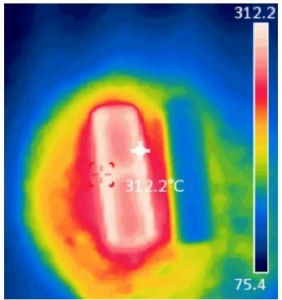

● Hmatoorada xawliga ah: Matoorada xawaarahoodu sarreeyo, taas oo macnaheedu yahay in xawaaruhu u dhexeeyo 30,000-200,000RPM, si loo xakameeyo qulqulka qulqulka iyo in la yareeyo kulaylka ayaa ah shuruudaha ugu muhiimsan. Jaantuska 3 wuxuu muujinayaa heerkulka isbarbardhigga ee magnetka SmCo ee caadiga ah iyo SmCo-da hadda jirta ee anti-eddy ee 2600Hz. Marka heerkulka magnets-ka caadiga ah ee SmCo (ka bidix ee cas) uu dhaafo 300 ℃, heerkulka anti-eddy magnets SmCo hadda (bule one) kama badna 150 ℃.

●Mashiinnada MRI: Yaraynta qulqulka qulqulka ayaa muhiim u ah MRI si loo ilaaliyo xasilloonida nidaamyada.

Tignoolajiyada hadda jirta ee ka-hortagga ah ayaa aad muhiim ugu ah hagaajinta waxqabadka NdFeB iyo magnets-ka SmCo ee codsiyo badan. Adeegsiga tignoolajiyada lamination, kala qaybinta, iyo dahaadhka, qulqulka qulqulaya waxa si weyn hoos loogu dhigi karaa "Awoodda Magnet". Magnet-ka NdFeB iyo SmCo-ka-hortagga ah ee hadda jira ayaa suurtagal ah in lagu dabaqo nidaamyada korantada ee casriga ah.

Waqtiga post: Seb-23-2024