●Sintered NdFeB umazibuthezisetyenziswe ngokubanzi kwiimpawu zazo ezimangalisayo zemagneti. Nangona kunjalo, ukunganyangeki komhlwa kweemagnethi kuthintela ukusetyenziswa kwabo ngokuqhubekayo kwizicelo zorhwebo, kunye nokwaleka komphezulu kuyafuneka. Iingubo ezisetyenziswa ngokubanzi okwangoku ziquka i-electroplating Ni-iingubo ezisekelwe, i-electroplating Zn-esekelweiingubo, kunye ne-electrophoretic okanye i-spray epoxy coatings. Kodwa ngenkqubela phambili eqhubekayo yetekhnoloji, iimfuno zokwalekaof NdFeBnazo ziyanda, kwaye iileya ze-electroplating eziqhelekileyo ngamanye amaxesha azikwazi ukuhlangabezana neemfuno. Itekhnoloji ye-Al esekwe kusetyenziswa itekhnoloji yokubeka umphunga (PVD) ineempawu ezibalaseleyo.

● Ubuchule bePVD obunjengokutshiza, i-ion plating, kunye ne-evaporation plating zonke zinokufumana izinto ezikhuselayo. Itheyibhile 1 idwelisa imigaqo kunye neempawu zokuthelekisa iindlela ze-electroplating kunye ne-sputtering.

Itheyibhile 1 Iimpawu zokuthelekisa phakathi kweendlela ze-electroplating kunye ne-sputtering

I-Sputtering yinto yokusebenzisa amasuntswana anamandla aphezulu ukubhobhoza indawo eqinileyo, ebangela iiathomu kunye neeathomu ezikumphezulu oqinileyo ukutshintshiselana ngamandla e-kinetic ngala masuntswana anamandla aphezulu, ngaloo ndlela atshiza aphume kumphezulu oqinileyo. Yafunyanwa okokuqala nguGrove ngo-1852. Ngokwexesha layo lophuhliso, kuye kwakho ukutshiza kwesibini, ukutshiza kwenqanaba eliphezulu, njalo njalo. Nangona kunjalo, ngenxa yokusebenza kakuhle kwe-sputtering ephantsi kunye nezinye izizathu, ayizange isetyenziswe ngokubanzi kude kube ngowe-1974 xa iChapin yenza i-balanced magnetron sputtering, isenza isantya esiphezulu kunye nobushushu obuphantsi bube yinyani, kwaye iteknoloji ye-magnetron sputtering yakwazi ukukhula ngokukhawuleza. I-Magnetron sputtering yindlela yokutshiza eyazisa imimandla ye-electromagnetic ngexesha lenkqubo yokutshiza ukunyusa izinga le-ionization ukuya kwi-5% -6%. Umzobo weskimu we-balanced magnetron sputtering uboniswe kuMfanekiso 1.

Umzobo 1 Umzobo womgaqo we-balanced magnetron sputtering

Ngenxa yokumelana nokugqwesa kwayo okugqwesileyo, i-Al coating ifakwe nguion umphungadeposition (IVD) isetyenziswe nguBoeing njengebambela le-electroplating Cd. Xa isetyenziselwa i-Sintered NdFeB, ikakhulu inezi ncedo zilandelayo:

1.High amandla okuncamathelisa.

Amandla ancamathelayo e-Al kunyeNdFeBngokubanzi ≥ 25MPa, lo gama amandla okuncamathelisa eqhelekileyo electroplated Ni kunye NdFeB malunga 8-12MPa, kunye namandla okuncamathelisa electroplated Zn kunye NdFeB malunga 6-10MPa. Olu phawu lwenza i-Al/NdFeB ilungele nasiphi na isicelo esifuna amandla ancamatheleyo aphezulu. Njengoko kubonisiwe kwi-Figure 2, emva kokutshintshana imijikelo ye-10 yempembelelo phakathi (-196 ° C) kunye (200 ° C), amandla okunamathela kwi-Al coating ahlala ebalaseleyo.

Umfanekiso wesi-2 ifoto ye-Al/NdFeB emva kweempembelelo zebhayisikile ezili-10 ezitshintshanayo phakathi kwe-(-196 ° C) kunye (200 ° C)

2. Gxuma kwiglue.

I-Al coating ine-hydrophilicity kunye ne-angle yoqhagamshelwano yeglue encinci, ngaphandle komngcipheko wokuwa. Umzobo 3 ubonisa i38mN umphezuluulwelo loxinzelelo. Ulwelo lovavanyo lusasazeke ngokupheleleyo kumphezulu we-Al coating.

Figure 3. uvavanyo lwe-38mN umphezuluUxinzelelo

I-3.I-magnetic permeability ye-Al iphantsi kakhulu (i-relative permeability: 1.00) kwaye ayiyi kubangela ukukhuselwa kweepropati zemagneti.

Oku kubaluleke kakhulu ekusetyenzisweni kweemagnethi ezincinci kwintsimi ye-3C. Ukusebenza komphezulu kubaluleke kakhulu. Njengoko kubonisiwe kuMfanekiso 4, kwikholamu yesampula ye-D10 * 10, impembelelo ye-Al yokwambathisa kwiipropati zamagnetic incinci kakhulu.

Umzobo we-4 Utshintsho kwiipropathi zamagnetic ze-NdFeB ye-sintered emva kokubeka i-PVD Al yokugquma kunye ne-electroplating ye-NiCuNi yokugqoka phezu komhlaba.

4.Ukufana kobunzima bungcono kakhulu

Kuba ifakwe kwimo yee-athomu kunye namaqela e-atom, ubukhulu be-Al coating buyalawuleka ngokupheleleyo, kwaye ukufana kobunzima bungcono kakhulu kunobo be-electroplating coating. Njengoko kubonisiwe kuMfanekiso 5, i-Al coating inobunzima obufanayo kunye namandla ancamathelayo.

Umzobo5 icandelo elinqamlezayo le-Al/NdFeB

5.Inkqubo yokubeka iteknoloji yePVD ihambelana ngokupheleleyo nokusingqongileyo kwaye akukho ngxaki yongcoliseko lwendalo esingqongileyo.

Ngokweemfuno ezisebenzayo, itekhnoloji ye-PVD inokufaka i-multilayers, njenge-Al/Al2O3 i-multilayers enokumelana nokugqwesa okugqwesileyo kunye neengubo ze-Al/AlN ezineempawu ezibalaseleyo zoomatshini. Njengoko kuboniswe kwi-Figure 6, i-cross-sectional structure ye-Al / Al2O3 yokugqoka i-multilayer.

Fumfanekiso 6Umnqamlezo icandeloka-Al/Al2O3 multilyaers

Okwangoku, ezona ngxaki ziphambili zithintela ukwenziwa kwemveliso ye-Al coatings kwi-NdFeB zezi:

(1) Amacala amathandathu umazibuthe abekwe ngendlela efanayo. Imfuneko yokhuseleko umazibuthe kukufaka isambatho esilinganayo kumphezulu wangaphandle umazibuthe, efuna ukusonjululwa komjikelezo-ntathu wemagnethi kwi-batch processing ukuqinisekisa ukuhambelana komgangatho wokwambathisa;

(2) Inkqubo yokuqhawula i-al-coating. Kwinkqubo yokuveliswa kwamashishini amakhulu, akunakuphepheka ukuba iimveliso ezingafanelekanga ziya kuvela. Ngoko ke, kuyimfuneko ukususa i-Al-coating engafanelekanga kunyekhusela kwakhonangaphandle kokonakalisa ukusebenza kweemagnethi zeNdFeB;

(3) Ngokwemeko ethile yesicelo, iimagnethi ze-NdFeB ezine-sintered zinamabanga amaninzi kunye neemilo. Ke ngoko, kuyafuneka ukufunda iindlela ezifanelekileyo zokukhusela amabakala ahlukeneyo kunye neemilo;

(4) Ukuphuhliswa kwezixhobo zokuvelisa. Inkqubo yokuvelisa idinga ukuqinisekisa ukusebenza kakuhle kwemveliso, efuna ukuphuhliswa kwezixhobo zePVD ezifanelekileyo kwiNdFeB yokukhusela imagnethi kunye nokusebenza kakuhle kwemveliso;

(5) Ukunciphisa iindleko zokuvelisa iteknoloji yePVD kunye nokuphucula ukukhuphisana kwemarike;

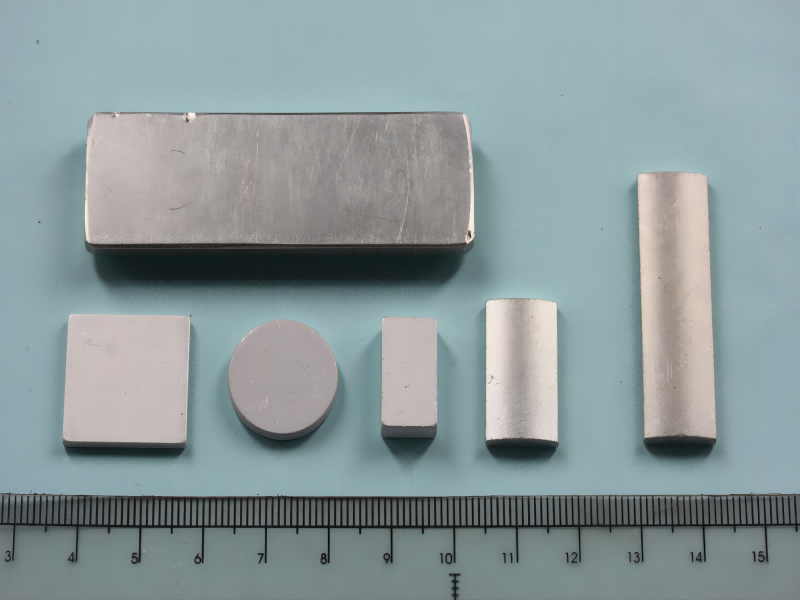

Emva kweminyaka yophando kunye nophuhliso lwamashishini. I-Hangzhou Magnet Power Technology iye yakwazi ukubonelela ngeemveliso ezininzi zePVD Al ezifakwe kubathengi. Njengoko kuboniswe kwi-Figure 7, iifoto ezifanelekileyo zemveliso.

Umzobo 7 Al coated NdFeB umazibuthe ngeemilo ezahlukeneyo.

Ixesha lokuposa: Nov-22-2023