●Sintered NdFeB ozibutheziye zasetshenziswa kabanzi ngenxa yezakhiwo zazo ezimangalisayo kazibuthe. Kodwa-ke, ukumelana nokugqwala okungekuhle kozibuthe kuphazamisa ukusetshenziswa kwabo okuqhubekayo ezinhlelweni zezentengiselwano, futhi ukumbozwa kwendawo kuyadingeka. Izingubo ezisetshenziswa kabanzi okwamanje zihlanganisa i-electroplating Ni-esekelwe ezinengilazi, electroplating Zn-sekelweama-coatings, kanye ne-electrophoretic noma i-spray epoxy coatings. Kodwa ngentuthuko eqhubekayo yobuchwepheshe, izidingo zokugqokaof NdFeBnazo ziyanda, futhi izingqimba ezivamile ze-electroplating ngezinye izikhathi azikwazi ukuhlangabezana nezidingo. I-Al based coating efakwe kusetshenziswa ubuchwepheshe be-physical vapor deposition (PVD) inezici ezinhle kakhulu.

● Izindlela ze-PVD ezifana ne-sputtering, i-ion plating, ne-evaporation plating zingathola izimbotshana zokuzivikela. Ithebula 1 libala izimiso nezici zokuqhathaniswa kwezindlela ze-electroplating nezindlela zokufafaza.

Ithebula 1 Izici zokuqhathanisa phakathi kwezindlela ze-electroplating kanye ne-sputtering

I-Sputtering isenzakalo sokusebenzisa izinhlayiya ezinamandla amakhulu ukuze kuqhume indawo eqinile, okubangela ama-athomu nama-molecule endaweni eqinile ukushintshanisa amandla e-kinetic ngalezi zinhlayiya ezinamandla amakhulu, ngaleyo ndlela ephuma endaweni eqinile. Itholwe okokuqala nguGrove ngo-1852. Ngokwesikhathi sokukhula kwayo, kube khona ukuphalaza kwesibili, ukuphalaza kwamabanga aphezulu, nokunye. Kodwa-ke, ngenxa yokusebenza kahle kokuchaphaza okuphansi nezinye izizathu, ayizange isetshenziswe kabanzi kwaze kwaba ngu-1974 lapho uChapin esungula i-sputtering ye-magnetron elinganiselayo, okwenza i-sputtering enesivinini esikhulu kanye ne-low-tempering ibe ngokoqobo, kanye nobuchwepheshe be-magnetron sputtering bakwazi ukuthuthuka ngokushesha. I-Magnetron sputtering iyindlela yokuphalaza eyethula izinkambu ze-electromagnetic ngesikhathi senqubo yokufafaza ukuze kwenyuswe izinga le-ionization liye ku-5% -6%. Umdwebo wohlelo lwe-balanced magnetron sputtering uboniswa kuMfanekiso 1.

Umfanekiso 1 Umdwebo wesimiso we-balanced magnetron sputtering

Ngenxa yokumelana nokugqwala okuhle kakhulu, i-Al coating ifakwe nguion umhwamukoi-deposition (IVD) isetshenziswe i-Boeing njengebambela i-electroplating Cd. Uma isetshenziselwa i-Sintered NdFeB, ngokuyinhloko inezinzuzo ezilandelayo:

1.High amandla okunamathela.

Amandla okunamathela we-Al kanyeNdFeBngokuvamile ingu-≥ 25MPa, kuyilapho amandla okunamathisela e-electroplated ajwayelekile e-Ni ne-NdFeB cishe angu-8-12MPa, futhi amandla okunamathela e-electroplated Zn ne-NdFeB cishe angu-6-10MPa. Lesi sici senza i-Al/NdFeB ilungele noma yiluphi uhlelo lokusebenza oludinga amandla aphezulu okunamathela. Njengoba kuboniswe kuMfanekiso 2, ngemva kokushintshanisa imijikelezo engu-10 yomthelela phakathi kuka-(-196 ° C) no (200 ° C), amandla okunamathela e-Al coating ahlala emuhle kakhulu.

Umfanekiso 2 wesithombe se-Al/NdFeB ngemuva kwemithelela engu-10 eshintshanayo yomjikelezo phakathi kuka-(-196 ° C) kanye (200 ° C)

2. Gcoba ku-glue.

I-Al coating ine-hydrophilicity futhi i-angle yokuxhumana yeglue incane, ngaphandle kwengozi yokuwa. Umdwebo 3 ukhombisa i-38mN phezuluuketshezi lwe-tension. Uketshezi lokuhlola lusakazwa ngokuphelele ebusweni be-Al coating.

Figure 3. ukuhlolwa kwe-38mN phezuluukungezwani

3.Ukungena kazibuthe kwe-Al kuphansi kakhulu (ukufinyeleleka okuhlobene: 1.00) futhi ngeke kubangele ukuvikelwa kwezakhiwo kazibuthe.

Lokhu kubaluleke kakhulu ekusetshenzisweni kozibuthe bevolumu encane emkhakheni we-3C. Ukusebenza kwangaphezulu kubaluleke kakhulu. Njengoba kuboniswe kuMfanekiso 4, kukholomu yesampula ye-D10 * 10, umthelela we-Al coating kuzakhiwo kazibuthe mancane kakhulu.

Umfanekiso 4 Izinguquko ezimpahleni kazibuthe ze-NdFeB ene-sintered ngemva kokufaka i-PVD Al coating kanye ne-electroplating NiCuNi coating phezulu.

4.Ukufana kokuqina kungcono kakhulu

Ngenxa yokuthi ifakwe ngendlela yama-athomu namaqoqo e-athomu, ubukhulu be-Al coating buyalawuleka ngokuphelele, futhi ukufana kogqinsi kungcono kakhulu kunokwembozo ye-electroplating. Njengoba kukhonjisiwe kuMfanekiso 5, i-Al coating inokuqina okufanayo namandla amahle kakhulu okunamathela.

Umfanekiso5 ingxenye ye-Al/NdFeB

5.Inqubo yokubeka ubuchwepheshe be-PVD ihambisana ngokuphelele nemvelo futhi ayikho inkinga yokungcoliswa kwemvelo.

Ngokwezidingo ezingokoqobo, ubuchwepheshe be-PVD bungaphinda bufake izendlalelo eziningi, njenge-Al/Al2O3 multilayers enokumelana nokugqwala okuhle kakhulu kanye nezingubo ze-Al/AlN ezinezakhiwo ezinhle kakhulu zomshini. Njengoba kuboniswe kuMfanekiso 6, ukwakheka kwe-cross-sectional ye-Al/Al2O3 ye-multilayer coating.

Figebe 6Isiphambano ingxenyekwe-Al/Al2O3 multilyaers

Njengamanje, izinkinga ezinkulu ezivimbela ukwenziwa kwezimboni kwe-Al coatings ku-NdFeB yilezi:

(1) Izinhlangothi eziyisithupha zikazibuthe zifakwe ngendlela efanayo. Imfuneko yokuvikela uzibuthe iwukuba idiphozi i-coating efanayo endaweni yangaphandle kazibuthe, edinga ukuxazulula ukuzungezisa kukazibuthe ekucubunguleni inqwaba ukuze kuqinisekiswe ukuhambisana kwekhwalithi yokunameka;

(2) Inqubo yokukhumula i-al coating. Enqubweni yokukhiqiza yezimboni ezinkulu, akunakugwemeka ukuthi kuzovela imikhiqizo engafanelekile. Ngakho-ke, kuyadingeka ukususa i-Al coating engafanelekile futhivikela kabushangaphandle kokulimaza ukusebenza kwamagnetic we-NdFeB;

(3) Ngokwendawo ethile yohlelo lokusebenza, omazibuthe be-NdFeB abanamabanga amaningi kanye nokuma okuningi. Ngakho-ke, kuyadingeka ukutadisha izindlela zokuzivikela ezifanele zamabanga ahlukene kanye nokwakheka;

(4) Ukuthuthukiswa kwemishini yokukhiqiza. Inqubo yokukhiqiza idinga ukuqinisekisa ukusebenza kahle kokukhiqiza, okudinga ukuthuthukiswa kwemishini ye-PVD efanele ukuvikelwa kuzibuthe kwe-NdFeB kanye nokusebenza kahle kokukhiqiza okuphezulu;

(5) Yehlisa izindleko zokukhiqiza ubuchwepheshe be-PVD futhi ithuthukise ukuncintisana kwemakethe;

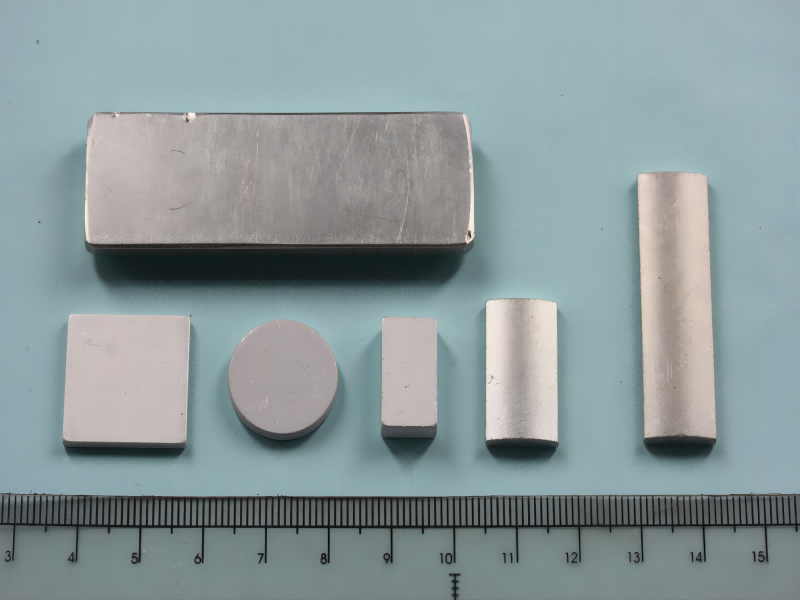

Ngemva kweminyaka yocwaningo nokuthuthukiswa kwezimboni. I-Hangzhou Magnet Power Technology ikwazile ukuhlinzeka ngenqwaba yemikhiqizo egcwele i-PVD Al kumakhasimende. Njengoba kuboniswe kuMfanekiso 7, izithombe zomkhiqizo ezifanele.

Umfanekiso 7 Ozibuthe be-NdFeB abahlanganiswe ngezinhlobo ezahlukene.

Isikhathi sokuthumela: Nov-22-2023